This damn irritating feature ( loud screech every time I move off after

starting up, when washers used and again when turn engine off )is

driving me nuts, today ive spent ages trying to stop this by dribbling

oil down the pushrod that comes thru the drivers wiper spindle to no

avail, it seems to have a seal around it obviously to stop stuff

getting in.

Removed the wiper and the trim below the screen but that

affords no more accsess to the motor and gearbox or whatever mechanism

it is, tried to pull the pushrod out but it only lifts about 5mm then

comes to a definate stop!

Think I am going to try and get a syringe

with the needle still on and try shoving it between pushrod and seal

and inject some oil in to it, wot you reckon?

These pictures might help...

The complete assembly:

With the main part of the wiper console removed:

With the connecting (pivoting) arm removed, leaving the rod that moves

up and down:

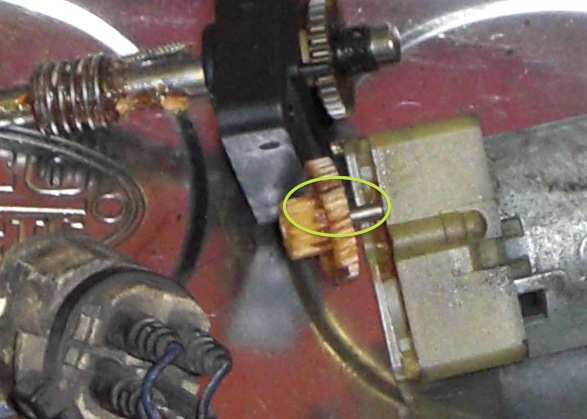

The

motor. The round black disc doesn't turn. Underneath it is the gearing

that pushes the rod up and down (the brass bit is the bit that moves):

If you've already lubricated the rod that moves inside the shaft of the

connecting arm, then the only other part that could (in my opinion)

make a noise is the gearing under the black disc. It might be worth

spraying a lot of WD40 around the edges of the black disc (and hope it

penetrates around the edges...) to see if that helps.

Cheers

for those photos they at least show me whats what, like you say its the

gearing thats probably making the row, I must have put half a can of

Douck oil all over the thing but as yet its not done, will still

try the syringe when I get one from somewhere.

Are these bits from your car?

If

they are can you detail whats involved in removing the offending motor

and drive from the car and i,ll get the lot out and strip the thing and

fix it once and for all!

If that fails I assume the power leads are

seen coming out the back of the motor itself, SNIP now make a noise! (

that will be last resort! )

The

wiper console is removed after first removing the blower motor via the

bulkhead behind/below the coolant expansion tank. The total job takes

between 2 - 4 hours. I don't have a scanner, but I can fax you the

relevant pages from the bentley if would like them. Yes, the parts are

from my car, I installed a replacement and kept the old one for spares.

try again to get some lube in without stripping it I have even

thought of trying to drill a small hole in the top of the gearbox cover

in situ and oiling it that way and then bunging the hole up again, do

you fancy taking that cover off to see whats under it and photoing it?

Thanks for your efforts already, much appreciated.

I tried to take the cover off but found it seemed to be held down by

something inside (other the screws), and since it's still working I

didn't want to break it. However, for the 'sake of science', I'll have

another go tomorrow evening. I'll let you know...

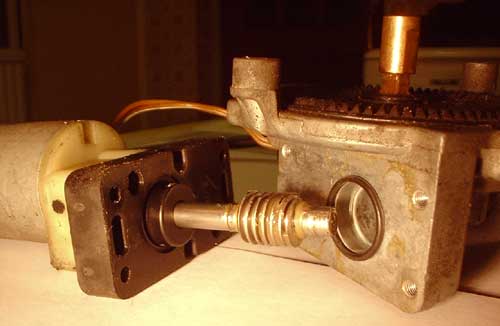

I still can't remove the black disc, but the motor can be and it's

possible to peer inside:

Inside is a large cog, which I presume is threaded in some way so that

as it turns it slowly moves up or down:

You

don't need to drill through the top of the black disc, there is a screw

at the back which gives direct access to the innards, new grease can be

applied quite easily (once it's out of the car...)

What a shame that screw isnt acessible in situ, it would save a lot of

hassle, sill wondering about making a hole in the top to save work, i

dont fancy having to remove the expansion tank and blower motor?

Mind you, you had to if your wipers themselves

were on the blink. Id've only a noise to put up with, everything else

is ok, touch wood! ( p.s. I did eventually replace the wiper stalk, some

bas"""d had glued the end, thats why it wouldnt pull off no matter how

much I tried, mashing it in the process!)

Really wish I had a manual at times like these.

A couple of thoughts have occurred to me. I'm guessing - but I think the

large internal cog will have a hollowed out centre, which will be

threaded, and screwed into this will be the rod that sticks out of the

black disc (with the brass end). When the motor turns the cog, the rod

(which will be fixed so that it doesn't turn) will screw up or down the

thread. So the key moving parts are:

* The motor auger and the large cog

* The threaded rod moving inside the thread of the cog

* The rod moving up and down.

I think the internal thread will be the point of the most contact, it

will have to be quite strong to withstand the force pushing down from

the spring of the wiper. The grease on the cog and auger still looks

quite fresh on mine, which may show that there isn't much 'happening'

between the two.

The reason why applying a lot of lubricant to the

rod, at the wiper end, may quite often be successful (for some people)

could be that the lubricant makes it's way down the rod, through the

gap between the rod and the hole in the centre of the black disk, and

penetrates the thread.

With these thoughts in mind, if I had this

problem I think I would still try to apply a lot of lubricant directly

to the centre of the black disc, then manually apply 12v to the motor

to move the rod up and down to help the lubricant penetrate the thread.

Through the cover at the base of the windscreen there are 2 accessible

electrical connectors, one of which I think must be for this motor (the

other for the windscreen wiper motor), and I've tried applying a

voltage to mine and it works, even with just 6v.

As jobs go, the

one removing the wiper console is actually quite a pleasant one. The

only problem I have is with the motor blower housing, it is in two

halves and I always struggle trying to get the two halves to meet

properly (it normally takes me around 20mins with a lot fiddling and

cursing.) Also, if you're going to take the console out then it's a

good time to lubricate the wiper linkages, and a washer can be added if

the wipers are hitting the bonnet.

As usual, please note that

I'm just thinking out loud (as if the problem was on my car), please be

cautious before acting on anything I've said. I would hate you to waste

a lot of time on this only to find out that what I've said hasn't

helped (or is blatantly incorrect)

I have this problem, pull fuse 22 and everything else will work fine but

the pressure motor will be off and hence no noise, better than snipping

the wire as you can always easily replace the fuse later if you fix the

motor.

Having seen the pics posted here I will take a second look at the motor

on mine.

I discovered this while having a nosey in the fuse box pretty soon after

getting the car, there is a sticker on the inside of the cover saying

what fuse is what and I noticed that fuse 22 was missing. So I

dutifully replaced it only to get a god awful grinding noise from the

front of the dash just after pulling off and using the wipers

(frightened the bloody life out of me I can tell you). The sticker says

fuse 22 is the Wiper Pressure Motor, nothing else, and without it I

have wipers and wash as normal and everything else works so not really

worried about the pressure motor. If you can't see it then maybe mines

got a different fuse box layout. What year is yours? I'll have another

look after work and count them in from the end and let you know.

Had another look and yes fuse 22..... pressure control ADV...AND...

headlight washers!

Mines an 89 735i SE, yours must have washers on the lights, are they

working? or is yours different?

It don't say nuffin about headlight washers in the fuse box but I do have

them. The book says they activate every third time the screen wash is

used so will have to test this. Last time I pressed the screen wash

while standing next the drivers door the screen wasn't the only thing

that got washed. Better put the waterproofs on