BMW's V-12 hydraulic camshaft chain tensioner contains an O-ring that hardens

over time and allows oil to seep past the O-ring and out through the

tension adjustment screw threads. This results in small puddles of oil

on the garage floor and an oil-soaked A/C compressor and drive belt.

This slow leakage does not affect the operating performance of the

tensioner.

The tensioner is located on the right front of the

engine, directly above the A/C compressor. Most tensioners still have

their “anti-tampering” cap in place, a black cylindrical plastic cap to

protect the adjustment screw from damage. Oil typically weeps along the

adjustment screw and exits the tensioner at the end of this cap, which

is open. Some tensioners have their protection cap missing, exposing

the adjustment screw and lock nut.

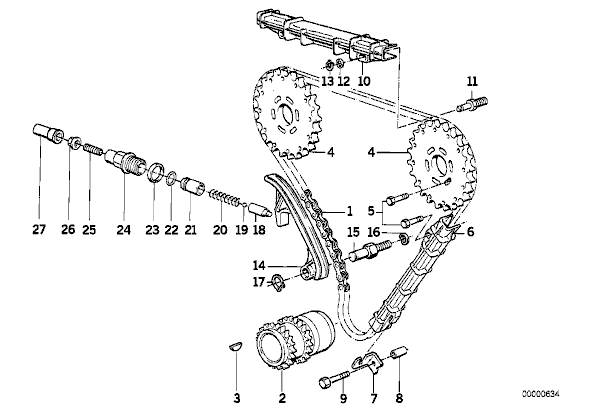

1. Tension set screw

2.

Set screw lock nut (17mm)

3. Screw plug (19 mm)

4.

Aluminum crush sealing ring (07 11 9 963 355)

5.

Dowell sleeve O-ring (11 31 1 702 953)

6. Dowell sleeve

7. Spring

8. Piston

You'll

need to purchase items 4 and 5 above, and also the anti-tampering cover

(11 31 1 720 006), which is not shown. You also need 17mm and 19mm deep

sockets and a torque wrench calibrated up to 50 NM.

The picture

below shows the location of the tensioner cap assembly on the engine,

just forward of the air conditioning compressor on the right, front,

lower section of the engine.

To gain access, remove the intake mass

airflow sensor and rubber ducting between the air cleaner housing and

the DK motor assembly. Also, disconnect the high tension lead from the

coil and carefully put aside. You'll need to remove the protection cap

(item 1 below left) by vigorously wiggling from side to side. It can't

be reused, so don't worry about damaging it.

Next, take your 17mm

socket and release the tensioner set screw locknut (item 2 above).

Leave it loose on the set screw (item 1) and give the set screw

precisely 1 counterclockwise turn to release a tiny bit of pressure off

the tensioner piston. Don't disturb the set screw any further, and

gently snug the lock nut back down onto the screw plug (item 3).

Next,

get your 19mm deep socket, fit over the screw plug, and giving a mighty

heave, unscrew the plug. Do not release the plug entirely from the

cylinder block. The piston inside is under considerable pressure and

will definitely damage hands if you're not prepared to press against it

when the screw threads release. Slowly unscrew the plug. When it

releases, a capful of oil will drain from the tensioner piston all over

the floor, so be prepared to catch it. Once free, you might have to

extract the piston (item from the bore by fishing around with your

little finger.

Now, using an Exacto knife, carefully nick and pry at

the O-ring (item 5) on the dowell sleeve (6). Do not scratch or

otherwise damage the dowell sleeve. The O-ring will be very hard and

sealed in its groove. Once free, clean the groove, replace the O-ring,

and replace the crush ring (item 4) on the screw plug.

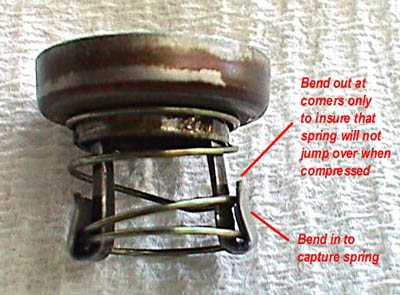

Now, time to

assemble everything. Insert the piston into the bore with the end of

your little finger, and press and rotate until you feel the end of the

piston "key" into the tensioner ramp. Here's a picture of the piston

engaging the ramp below on the left in item 1.

Now comes the hard

part. Seat the narrow end of the spring (7) into the dowell sleeve (6),

and seat the sleeve into the screw plug (3). I then put the screw plug

into my 19mm socket, guided the spring into the back of the piston, and

tried repeatedly to compress the spring enough to allow the screw plug

to engage a thread on the cylinder block. It's really tough, so take

your time. You'll get the hang of it after about 10 minutes. Once

you've got it threaded, torque the screw plug down with 40 NM.

Next,

turn the set screw 1 turn clockwise to restore the original tension

setting, and tighten the 17 mm set screw (2) down with 20 NM torque (my

guess - it's not in the specs). Place the protection cap on the set

screw and wiggle it snug onto the screw plug.

Because you've drained

a small catch reservoir the tensioner uses to feed oil to the piston,

the tensioner will need to be primed. If the right camshaft cover is

off, you can pour a small amount of oil down the right side of the

camshaft front cover, where it will fill the reservoir. Then insert a

long screwdriver (I used a wood paint mixing blade) and depress and

release the tensioner ramp repeatedly until it becomes resistant to

movement (see the A-B diagram above).

If you don't have the covers

off and the tensioner ramp accessible, I've been told the following

works pretty well. Set the OBC antitheft CODE feature of your car to

disable the ignition, crank the engine three times for 10 seconds each

time, and then disable the CODE feature to allow the engine to fire.

You'll probably hear a lot of chain slap for the next 30 seconds while

the reservoir fills and the tensioner piston primes. Degree of

difficulty: 5 on a scale of 10.

from the ever helpful Johan & Sean's site

This is without the anti-tamper cover

Jump to top |