Source: Nov-1988 750iL, no sunroof, left hand drive, manual rear window blind

Job: replace headliner

Time: say 6 hours, 2 people plus an occasional third

Guidelines:

1. Drop door rubbers from the top and both sides of all doors.

You can leave the lower scuff plates in place.

Drive the fronts seats forward as far as possible and remove the headrests –

they pull straight out – can be stiff.

2. C pillar facings

Pull rear seat sidelights from C pillar casing,

rear edge pulls out first.

Though

the space you can see (with torch) the top bayonet clip. Put your hand

in behind the clip and pull straight inwards. This releases the top of

the casing. The problem is that there are two lower plastic clips on

the casing that are brittle and fairly easy to break if you rush it.

The bottom of the casing is strongly pushed by the back seat so

carefully pull the edge of the seat away from the casing and with your

other hand as low down on the casing as possible, pull the casing

upwards at 20 degrees and forward. You should get both clips out intact.

Unplug the side lamp. That's one done now do the other!

fixing a broken C-pillar clip

2. B pillar Lower half casing

Move the front seat forward as far as possible.

With

a small flat screwdriver pop out the two plastic plugs on the lower

half casing. This frees the bottom of the casing. Swing the bottom out

about 10 cm and pull downward. This releases the top of the casing.

Upper half casing

With

the lower half casing off you can see the lower 2 bayonet clips on the

upper half casing. Pull straight inwards. There is another bayonet clip

at the top. Put your fingers behind the upper casing and pull down and

inwards.

Note: the upper metal clip can fall out of its socket in

the roof when you remove the upper casing. Make sure to replace it or

renew it; it’s all too easy to miss this when you’re putting the liner

back in.

3. Remove B pillar upper seat belt mounting nut (17 mm). This allows the casing to drop into the foot well.

Note:

If you want to recover this casing you’ll have to release either the

belt from the seat or release the belt reel from the bottom of the B

pillar. 17mm bolt. We took out the belt reel but now find that the

reassembled seat belts are somewhat slow to retract. If you can clean

the upper casing in the car you will save some time. We were thinking

to replace the covers but they cleaned up really well. Chalk this up to

experience.

4. "A" pillar casing

3 simple bayonet clips

running down the center of the casing. With fingers front and back of

the casing, pull in towards the center of the car. Start with the top

clip, then middle, then bottom.

5. Grab handle mounting screws

Note:

each handle is secured to the board by two small plastic plugs. Do not

try to pull the handles off the board – just remove the mounting screws.

Pull

the handle down and remove the small caps with a small flat

screwdriver. Take out the two nice large cross head screws. This is not

as easy as you might think as the spring retractors tend to load the

headliner board as the screws come out. Three hands are definitely

useful to preserve the board. One person has to hold the base flat

against the board while the other holds the handle down and wields the

driver.

6. Rear vision mirror

Turn

the mirror’s stem and base anti-clockwise about 45 degrees. This should

release the mirror. Remember the feel of it coming off as you will have

to reinstall it later.

7. Remote control switch

With your fingernails pull the remote down and unclip the wiring.

8. Vanity mirror light assembly

As per 7.

9. Main ceiling light assembly

As

per 7. In our case it seemed that it was easiest to remove the

left-hand end first. There is no easy electrical plug at here so leave

the assembly hanging down.

10. Recommendation. At this point –

particularly if you’re working alone – pass two simple straps over the

roof and under the headliner – one through each door opening. Once you

start to release the front and rear board attachments these straps

should stop the board from sagging and breaking. No need to be really

tight.

11. Sun visor base and end clip < 2 damn torx screws each>

The guy who invented these is not my friend.

Regardless,

take out the screws and disconnect the wiring. One novelty of this car

is that everything imaginable (and then some) is wired up. These

electrical fittings are simple spade connectors and can be really tight

– have a small pair of needle nose pliers handy!

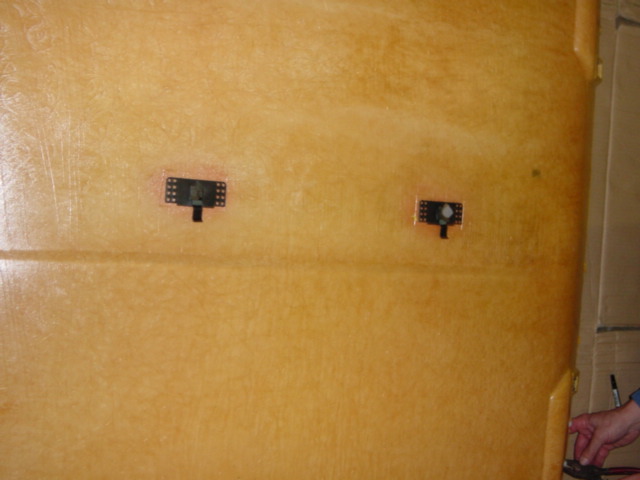

12. Rear window blind holders

Unscrew and remove (for some reason there is no electrical connector)

13. Da board

Work

your fingers between the board and the windscreen. In Shogun’s car the

liner here was stuck to the windscreen sealant. Slowly pressure the

liner material in 4cm sections and it should pull away from the

windscreen.

There are two clips on the rear edge of the board – they are about 5cm

inboard from the blind holders. Put your fingers under the board and

pull down.

The board is now pulled backwards about 10cm which should release the clips in the center of the board.

14. Removing the board

We

were quite surprised to find that the board was in excellent condition

and had retained its flexibility -- no cracks in this beauty. This made

it relatively easy to remove -- but two people definitely recommended.

Raise the passenger’s seat up as far as possible and put the driver’s seat as far down as possible.

Release the straps and lower the board.

Get on your 3d glasses.

Turn the board clockwise (looking down on the board) and raise the righthand edge. Move it as far forward as possible.

Raise the driver’s seat all the way. 5 hands would help here.

You now can drop the left side of the board down further.

Slightly

bow the board (particularly the back right corner to get it past the

left C pillar) and drop the back left corner of the board into the rear

foot well.

The board can now be slid out through the rear left door – this is a 750iL after all.

If you’ve been paying close attention you now know how to put it back in again.

Once out of the car, remove the plastic pins holding the grab handles.

15. Removing the old foam

The old liner should simply fall away from the board. Treat the old foam

with respect. On Shogun’s car the foam turned to difficult-to-remove

sludge if it was pushed or smeared. The best attack was to use a vacuum

cleaner with the small corner nozzle. In most places, simply lightly

dragging the nozzle across the board was enough to remove 99% of the

foam. Stiff scrubbing brushes worked well in the recessed areas. To

prep the surface it seems that steel wool pads with concentrated

detergent worked best. The final surface was really smooth and

tack-free.

16. Fixing the new liner

Since

Shogun had carefully sized the new stock, we chose the easy way -- glue

first and trim later. The 3M glue Shogun got can be used as regular

direct glue or contact glue. We decided to proceed in strips using it

as direct glue.

With the board flat and the inside facing up, we

laid the new liner out and folded the rear half back. Starting from

roughly the center, we painted the board with glue in 15cm inch strips

from side to side – no glue was put on the edges or backside of the

board.

One problem is that the glue was yellow, same color as the

board. It helps to have another set of eyes checking for dry areas. We

used the glue direct from the can without any thinner. That

necessitated a stiff brush to get good adhesion and a thin even film.

We put down a 50% film, you could see the board thru the glue but only

just. The glue sets quickly and the 15cm strips seem to be good

compromise. Once the glue is down, spread out the liner to cover.

Luckily the glue sets quite quickly so in the cavities of the grab

handles it is relatively easy to push the liner in, hold for 1 minute

and it should stick. We did not tension the liner when we laid it down

and found that there were no wrinkles at the corners (my worry).

Warning: the rear corners are sharply curved and you’ll need care in

using enough glue to ensure that the material wraps smoothly and sticks

well.

The overwraps we left till later. We then did the front half.

Take a break because you’ll have worked up a sweat by now.

It’s essential that you have sharp craft knife and a pair of sharp scissors.

Take it from me, the material we used was damn tough to cut, probably

yours will be the same. One point is that all devices that pass through

the board really require the material to be cut out of the opening –

except the rear blind holders. I tried to cheat by leaving the material

in place but the stress seemed too much. My recommendation is to find

each corner of the opening with your finger, use the craft knife to

make a diagonal cut to the center, and then use the scissors to trim

the sides and ends. WARNING: there is precious little room for error

and it is very easy to cut the opening bigger than needed –trust me.

Keep the liner flat and the scissors vertical as you cut and do not

pull the material as it can stretch a lot. It’s better to be

conservative and cut twice.

For the small holes we used a small pointed soldering iron which melted the liner.

One

of the sun visor cavities was short of glue but when we cut out the

center light opening it was possible to carefully pull the liner away

and use a long thing stick to add more glue. Worked a treat.

We then turned the board over and laid it against some chairs.

Starting

with the rear end, we cut the corner reliefs so that the cuts ended 5mm

inch from the edge of the board. The idea is that when the liner is

wrapped over, the ends of the cuts are slightly past the edge of the

board. Cut the corner piece so it ends about 15mm from the edge of the

board – the width of corner was 5 mm at the bottom. Put down a dab of

glue and fold the corner piece down – hold until the glue sets.

Shogun’s material is as tough as boot leather and there was no worry

about the center piece breaking. We cut the rear liner to a width of 10

cm and folded it over after cutting out reliefs for the rear blind

holders and the two rear clips.

We then cut the material along the sides to a width of 15 mm and glued it down.

The front edge work followed the rear.

Refit the grab handles and hold with the plastic pins.

This design is marginal as the pins fall out if treated roughly.

17. Refitting the board

The reverse of removal.

Use the straps to hold the board up as working overhead is tiring and errors can happen.

The

trick here is to engage the center clips and then the rear clips. This

means that the board starts towards the back by about 20 cm, the center

clip holes are picked up, the slides forward past its final position by

about 1cm, the back edge is held up and the board is slid backwards to

engage the rear clips. Phew. 45 minutes of excitement in a few words.

Warning:

the center clips are not too strong and can be broken off if the board

is pushed forward too strongly. Fitting is easier if you turn the car

over on its roof – use a nice blanket to prevent paint damage.

Feed

the center interior light assembly through the hole so its hanging down

again. Feed those wires for the sun visors, vanity lights, and remote

control through the holes.

Refit the grab handle mounting screws.

3 hands needed here as if a plastic pin pops out its real difficult to refit it.

Refit the rear blind holders, and all the stuff at the front.

Note:

the hardest part seemed to be the sun visors and their end clips. It

was very difficult to get the screws lined up and started. I’d

recommend you buy a driver with a comfortable handle – it will give a

lot more control over the screws. Using an awl to line things up first

is really necessary.

Refit the pillar casings and the door rubbers.

You did remember to check that the bayonet clips were still in place above the B pillars before refitting the board, right?

Congratulate yourself.

Shogun is complaining that there is no sunroof -- what a joker!