The original BMW trunk shocks/pressurized spring are made by Stabilus-Boge,

Gas pressurized spring 490N 51241908431.

Cross Interchange Parts Factory Numbers of some of the various makers

BMW 51241908431

HK G10139

KLOKKE 00597100

FEBI Bilstein 01785

TRISCAN 871011203

STABILUS 1575BV

Magneti Marelli GS0924

The original ones are of course top quality but also pretty expensive from

the dealer or online shops. There are a lot of aftermarket ones available,

but I have also read that some are too long to fit. Searching the internet

I found Magneti Marelli units at a reasonable price for BMW series 7 E32 and

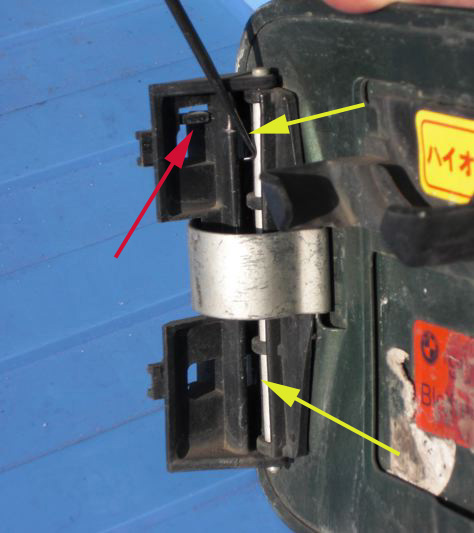

ordered them. Tried to install them. Installed one and the trunk lid could

not be closed anymore, it stayed up/open by about 5 cm. Reason was that

the rod of the shock hit the end of the damper = the unit is too long. As I had

ordered them overseas and paid for the freight, return and making a claim would be a

hassle.

So we modified them./b>

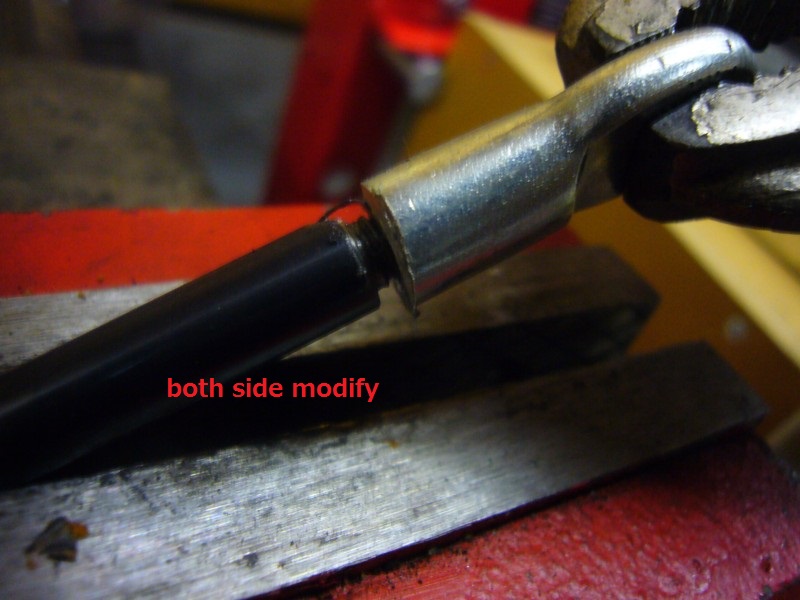

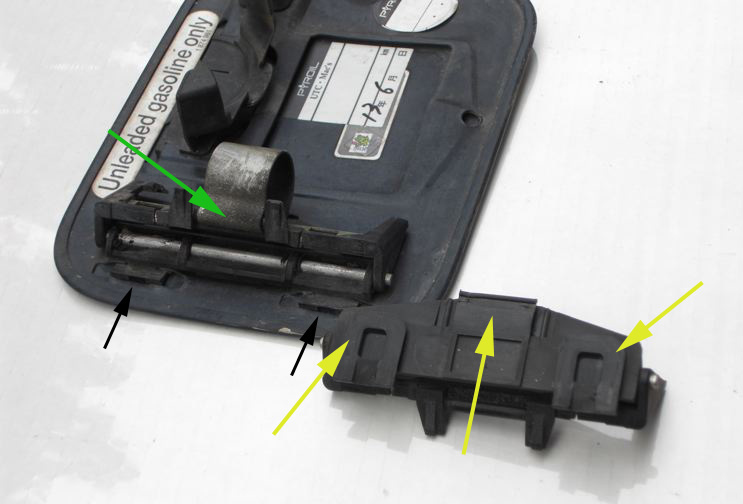

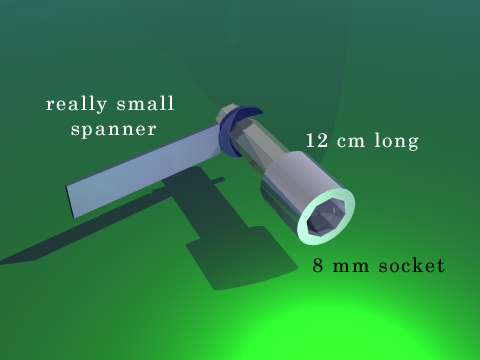

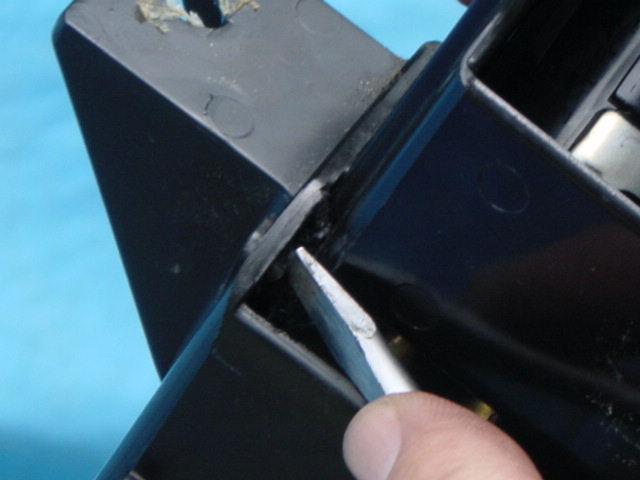

Found out that the mount on the rod is screwed on, so we

unscrewed the mounting hook and ground off about 5 mm from both the threaded

stud on the rod and the top clip with female thread.

Not all shocks will have the mounts screwed on, some will have them welded.

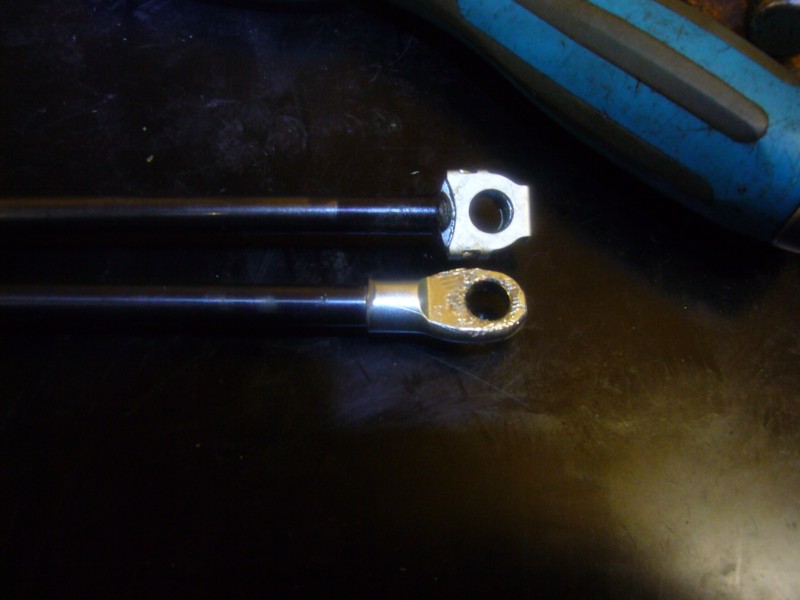

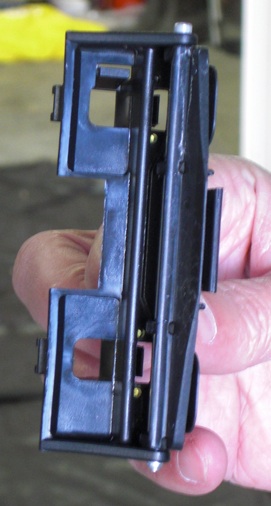

Here are pics before and after and to compare with the original, an original BMW gas

shock is also shown.